Manual ground-fault location can be implemented to meet the following requirements:

The essential difference in the two applications is in the significantly reduced test current for application in control circuits and/or the response sensitivity.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| Electrical safety - Product overview | Product Overviews | 4.8 MB | EN | 2024/03/0505.03.2024 | |

| 2020 Guidelines (US) | Technical Information | 1.9 MB | EN | 2020/06/1515.06.2020 |

Products

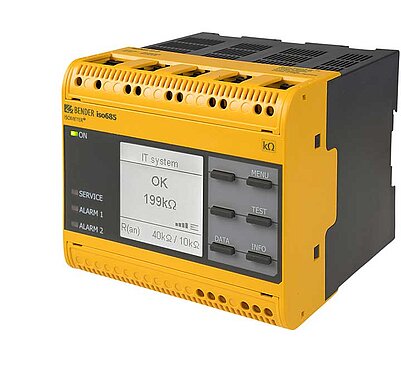

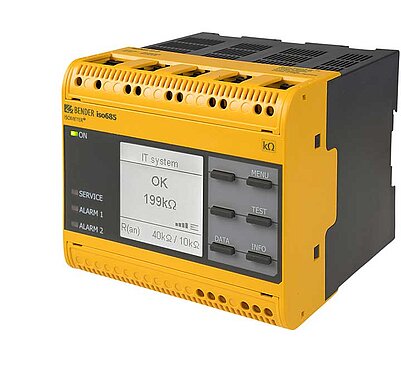

Ground-fault detector for ungrounded AC/DC systems

Ground-fault location module for ungrounded AC/DC systems

Ground-fault detector for ungrounded AC/DC systems

Ground-fault location module for ungrounded AC/DC systems